1-on-1 Technical Support

Professional Design Support

Elite Engineers & Technicians

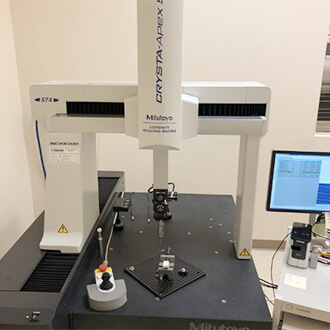

Quality control is an important aspect of every industry-whether it is products, parts, processes, tools or machines. Regardless of the industry, product quality is of paramount importance. In order to meet customer expectations, trade standards and industry regulations, Sinotekk uses different measuring instruments and tools to control the quality of CNC machined parts produced in our machining workshop.

1-on-1 Technical Support

Professional Design Support

Elite Engineers & Technicians

ISO 9001 Certified Factory

Strict Manufacturing Standards

Advanced Facilities

30-Day-Guarantee

Responsive Reply & Support

Genuine After-sales Policy

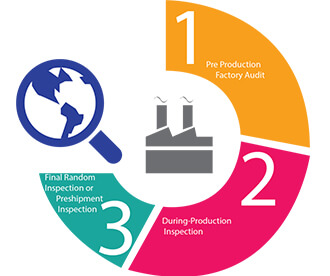

Inspections and Review for Every Stage of Production To conduct our extensive range of inspections, we use a wide variety of advanced equipment, including: ✔ Extensive incoming materials verification |  |

| Cutting-Edge Inspection Equipment To conduct our extensive range of inspections, we use a wide variety of advanced equipment, including: ● PolyMax Gun |

ISO Certification and Visual Quality Standard

Committed to the continual improvement of our industry-leading quality control and quality assurance processes, we are fully certified and compliant with ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, in addition to ISO 13485:2016 for medical products.

To ensure the highest level of aesthetic appeal alongside performance, we perform a visual quality inspection under controlled lighting and environmental conditions to confirm cosmetic appearance according to your specifications.