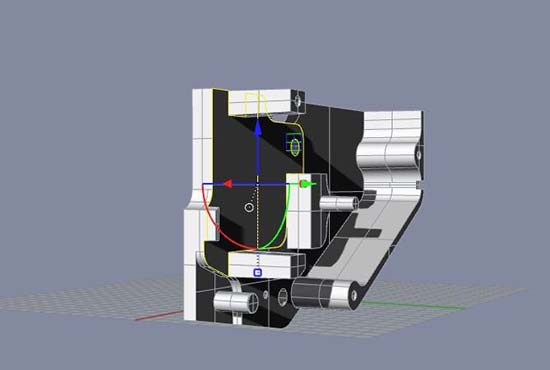

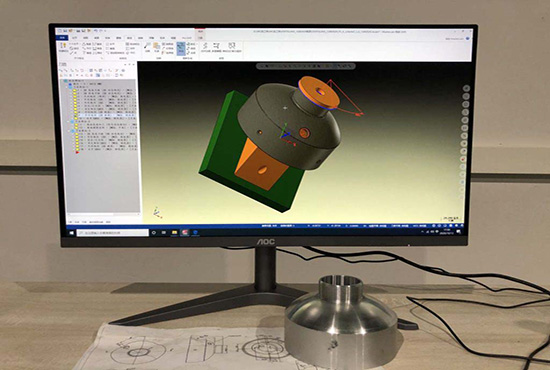

3D modelling

Sinotekk offers 3D modeling services as part of our product development process. Our team uses advanced CAD software to create accurate, detailed 3D models of parts and assemblies. These models help visualize and refine designs before production, enabling efficient prototyping and ensuring optimal performance. Whether you're developing a new product or improving an existing design, our 3D modeling services help bring your concepts to life with precision and clarity.