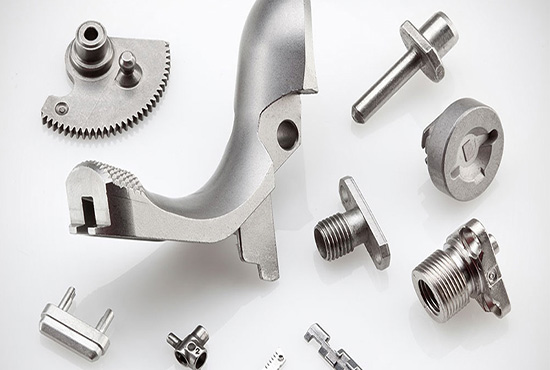

Leading Metal Injection Moulding company in China

The injection molding process starts by taking fine powder metallurgy and mixing it with a binder material. The product of mixing metal powders with a binder is called “feedstock.” In addition to producing a feedstock, a mold is also created for your final product. The feedstock is then injected into the mold where it is allowed to set and solidify. Once the injected metal has set, the binder removal procedure starts. This process varies depending on the type of binder initially employed.

Typically, there are multiple steps in the debinding process. Each part usually goes through more than one cycle to ensure maximum removal of the binding material before sintering. After debinding is finished, the part is semi-porous. This allows the secondary binder to more easily escape during the sintering cycle. Debinding is a critical step as without it the part would not be as sturdy.

Finally, the product must undergo a sintering process, which ensures that all the parts produced have the correct wall thickness, geometry, material composition, and physical properties. Using this process, a high volume of products can easily be made.