Leading CNC Milling Service company in China

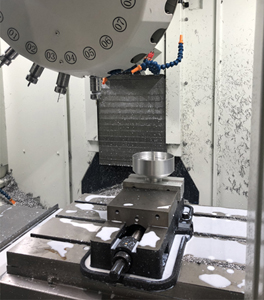

With a wide range of CNC milling capabilities, Sinotekk satisfies your high-precision machining needs in the most cost-effective way. We have 40+ CNC milling machines in house with 3, 4 and 5 axis. Here's a quick guide to explain what each added axis means in terms of milling operations and what kind of parts are produced on different CNC milling machines:

3-axis mill – The rotating tool can translate relative to the part on X, Y, and Z axes. The tool is fixed in a vertical or horizontal position, depending on the machine.

4-axis mill has all the axes mentioned above but now the table can also rotate around the X-axis. This allows to machine the sides of the workpiece without repositioning. It is worth mentioning that 4-axis mills are not that common.

5-axis mill – All that was true for 4-axis mills, applies for 5-axis ones as well. Only now the workpiece can also rotate around the Y-axis. 5-axis CNC milling machines can produce highly complex parts in one go, no extra setups are generally necessary.